|

H260 Trailer Mods, Maintenance and

Setup

Click to expand

The H260 Trailer is a fairly frequent

discussion item on the hunterowners.com forum. If you are

modifying a trailer to fit the H260, check these dimensions for the stock

trailer manufactured by Magic Tilt. The Majic Tilt trailer has

surge brakes on one axle. Virtually all boat trailers have surge

brakes while electric brakes are common on travel trailers.

However, since electricity, salt, and water really don't mix

well, electric boat trailer brakes are rare because they require

more maintenance.

A properly loaded trailer has about 9 - 12 percent of its

weight on the tongue. The stock trailer weighs 1280lbs. The

combined H260 trailer & boat combination weighs almost

5800 pounds with a tongue weight of 600 pounds including water,

engine. Adding the usual "stuff" probably adds another

250 pounds or so. Make sure you have a vehicle that is capable

of handling this load safely. There

is a lot more on this subject at this link.

Maintenance instructions for the

trailer are at this link: H260

Trailer Maintenance

Loading the trailer

The Magic Tilt

trailer for the H260 is versatile and durable. However, it is

sometimes hard to get the boat centered on the trailer.

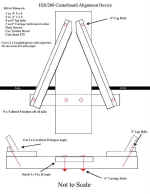

Many owners have added a keel alignment device so that the boat

automatically centers itself. Here's my approach.

|

click

any picture to expand |

|

|

|

|

|

Before: Misaligned

keel on bottom bunk |

|

|

|

|

|

Alignment device

construction pictures |

|

|

|

|

|

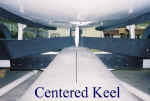

After: Properly

aligned keel |

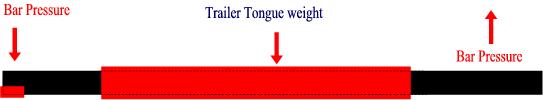

Binding on Trailer hitch extension

It can also be a

challenge to pull the tongue extension out. There is an upward pressure on

the ball end of the bar forcing the other end of the bar down

causing some binding. The lip welded on the cross piece at the

aft end of the tongue helps distribute the weight from the

forward to the back of the tongue.

Early

on, I tried to extend the tongue by hand but it was too

stiff. I greased the tongue but all that did was attract sand

and dirt making it even harder to slide in and out and I ended

up with black grease stains all over everything. What a mess!

Hunter recommends using the vehicle to extend the tongue. Some

people also advise slacking the winch cable before pulling the

extension out.

I have not

found a gentle way to do this. I block the trailer wheels and

use my car to extend and contract the tongue. This works OK for

pulling the bar out, but by using the car to slide it back in

place I have distorted the crossbar a couple of inches in the

middle where the tongue slams into the crossbar. Most of the

summer the boat is on a mooring, but when I dry slip the boat I

leave the tongue extended in between sails and I now try to keep

the tongue from slamming into the crossbar.

Inserting

the pin

Getting the extension pin in and out can also be a struggle. I

use a large heavy duty screwdriver to align the top and bottom

holes. One owner reports good results using a large marlin spike

to align the hole. Another has ground the stock pin to a

point. A hammer is sometimes needed to align the holes and drive

the pin home.

This year,

I'm going to take the whole thing out of the tube, clean it

good, straighten the cross bar, and try to come up with a better

technique for pulling the tongue in and out.

Click any Picture to Expand

Other Stuff:

The front roller can easily scratch the hull during loading.

Here's an idea for fixing this problem. Some owners have

replaced the black roller with the non-marking kind. Also, don't

forget to carry a spare tire and hub. Check the winch cable for

breaks. Also, check all bunk brackets on the trailer.

Click any picture to expand

|

|

Left: Stock bow roller

lasted two seasons & left black marks on bow

Right: This is the replacement roller.

Note the roller guard to prevent scratches to the bow when

loading the boat. |

|

|

Another owner alerted me to the possible problem

of broken trailer bunk brackets. When I checked, one was

broken completely. Bought several brackets from http://trailerpartsdepot.com

The item code is PT2060,Bunk,Bracket Angle (Mt Ld) $1.04

each. I bought 5 because that was the minimum order

quantity. |

|

|

Check the boat yard. How trailers

do not have a spare tire and hub?

The brakes/bearings on my trailer are

made by

Unique Functional Products (UFP). Go to the UFP website for

information on maintenance of trailer brakes and bearings

To extend the life of your tires here

are some suggestions:

For short term storage: Store in cool, dark place at

maximum inflation. Use tire covers to protect the tires

from direct sunlight.

For long term storage: Put the trailer on blocks to take

the weight off the tires, lower the air pressure and cover

tires to protect from direct sunlight. Care should be

taken to avoid prolonged tire contact with petroleum based

substances: oils, fuels and asphalt. Use thin plywood

sections between the tire and the pavement. Note: put

jacks and blocks under the axles not the frame.

Age: Trailer tires don't get enough miles on them to show

significant wear. Replace trailer tires every five to

seven years, whether they look like they're worn or not.

Other: After a blowout on a tandem-axle trailer, you

should consider replacing both tires on that side. The

remaining tire was likely subjected to excessive loading

and, as a consequence, may fail in the near future.

|

|

|

Nylon winch cable is easier on the hands

than wire.

|

Click HERE for More Pics and

Discussion on the H260 Trailer

|